(a) Department of Chemistry and NIS - INSTM, University of Turin, Via

Pietro Giuria 7, 10125, Torino, Italy

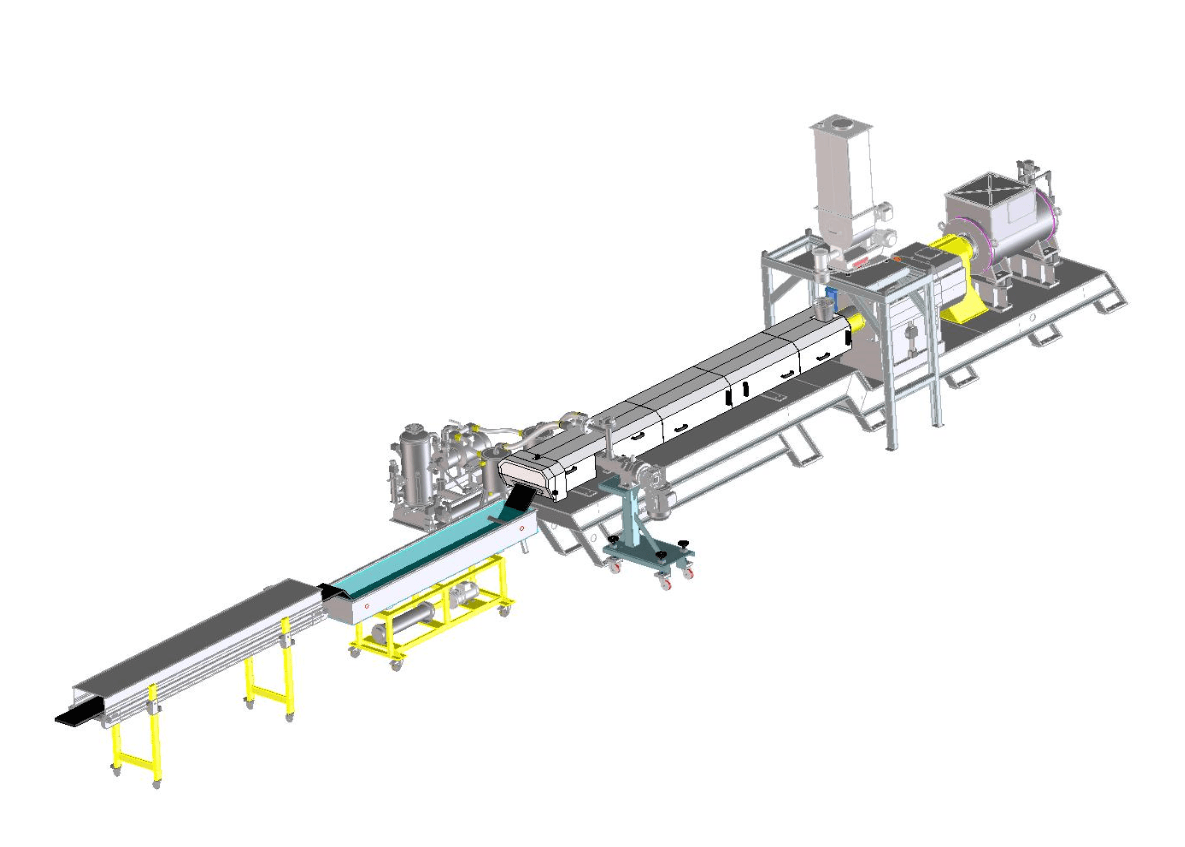

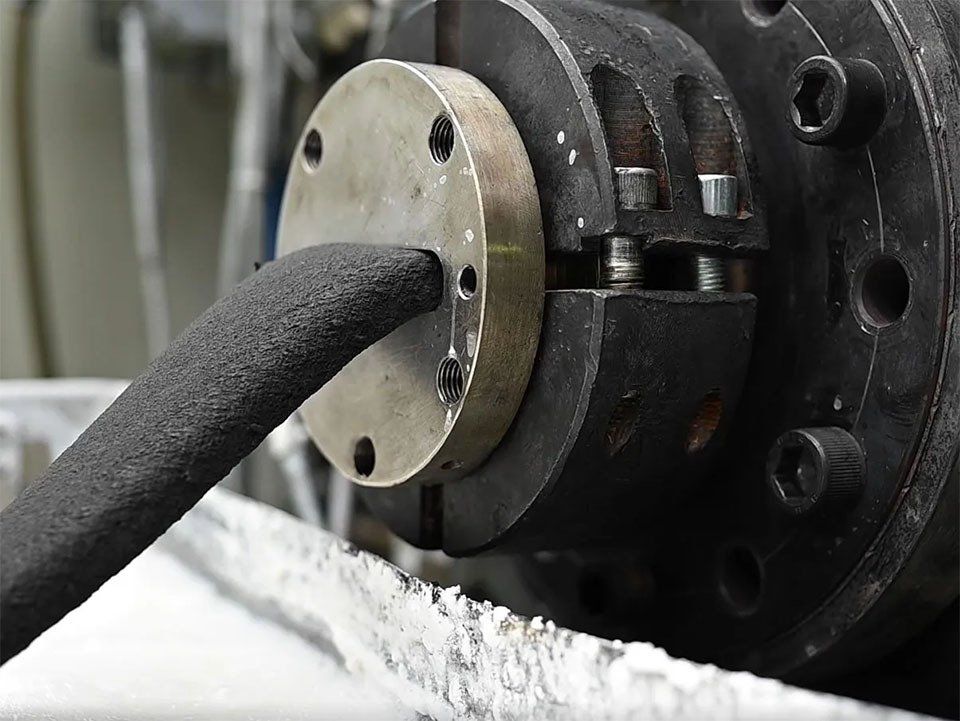

(b) F.lli Maris S.P.A.,

Corso Moncenisio 22, 10090, Rosta, TO, Italy

Under

the umbrella of the transition toward a circular economy, the evaluation of the

environmental sustainability of processes aiming to the recycling of materials

is essential. Rubbers, like ethylene-propylene diene monomer (EPDM), represent

a class of materials that have become an environmental, social and economic

issue, so the evaluation of the end-of-life management of these materials is of

primary relevance. This study investigates the environmental burdens associated

with a thermo-mechanical devulcanization process for recycling of EPDM wastes

by co-rotating twin-screw extruders. The Life Cycle Assessment methodology was

used to carry out the analysis and eight environmental impact categories have

been evaluated: Climate change, Ozone depletion, Photochemical ozone formation,

Acidification, Eutrophication (freshwater), Ecotoxicity (freshwater), Resource

use (fossils) and Resource use (minerals and metals). In the first step, the

analysis focused on the identification and quantification of main environmental

hotspots of the process. Then, the study was extended by including two

comparative analyses, to better understand the magnitude of the environmental

burdens generated by the devulcanization process. The results of the hotspots

analysis showed that the main contribution to the environmental impacts of the

devulcanization process is due to energy consumption. However, the comparison

underlines how the devulcanization process for recycling of EPDM waste allows

to reduce the environmental burden associated with the life cycle of rubber

products.

https://www.sciencedirect.com/science/article/abs/pii/S0959652622009775