Highly filled compounds

are particular materials with a high percentage of mineral filler dispersed

into a polymeric matrix that allow to considerably reduce production costs if

compared to the standard masterbatches.

In

order to increase extruders performances over the years, we have made numerous

technical process improvements maximizing - therefore - both the filler

percentage and the output capacity.

The most important

developments can be summarized in:

·

several Do/Di ratios which imply different free volumes;

·

a wide range of extruders with different specific torques;

·

the possibility to add the filler in four different feeding points (one

in the main feeding and three in the side feeding);

·

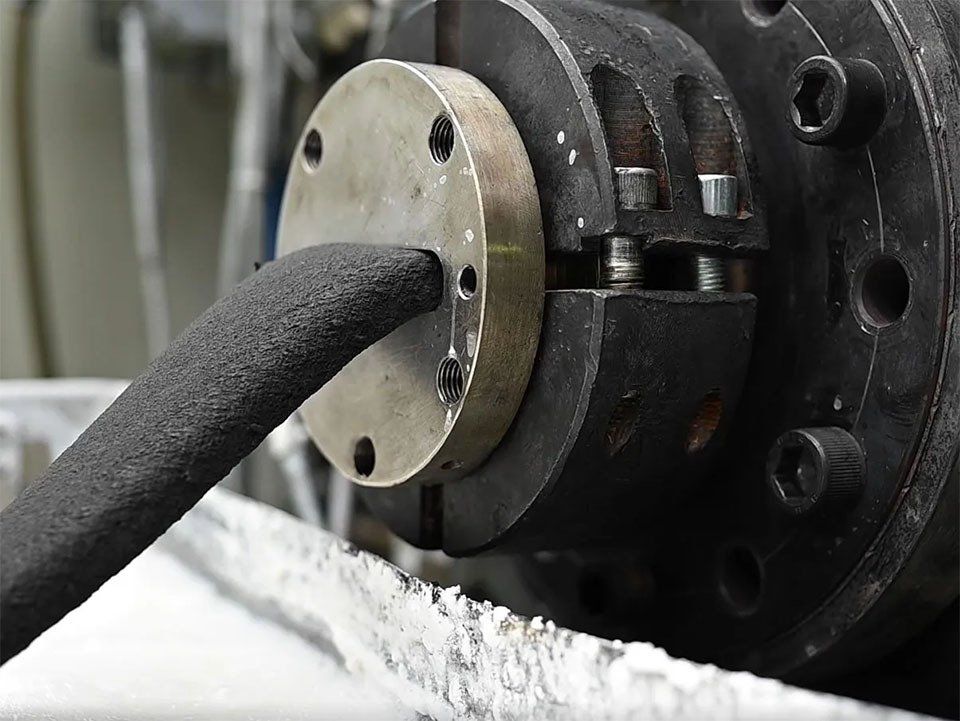

special equipment - including the deaeration system - to facilitate the introduction

of fillers that normally tend to incorporate air;

·

optimization of the screw profile and screw elements specific for this

particular process.

The synergy of these

technical solutions has allowed us to reach filler percentages up to 80-85%, preserving

the output capacity and keeping excellent dispersion standards. The achievement

of these excellent results has also been possible thanks to the formulations

and materials optimization from the Customers themselves.

Process layout of

highly filled compounds

To

verify the quality of highly filled compounds and their production efficiency,

it is possible to carry out tests at MARIS Technology Center.