DIE

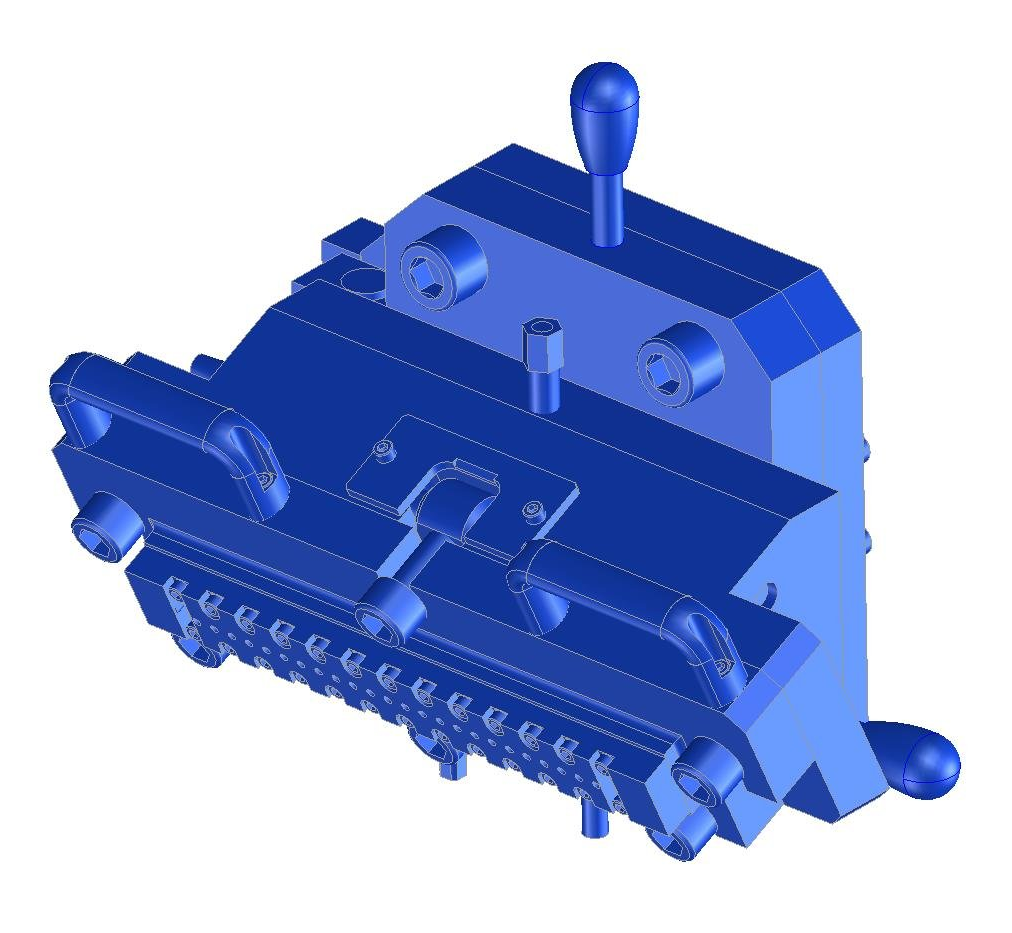

Our die is defined as quick-change, as disassembly takes place by loosening, but not removing, the fixing screws.

In this way, there will be no hot parts to handle and it will be possible to change the final part by lifting it from the special knobs and replacing it according to the cleaning needs or the need to change the number or size of the spaghetti to be obtained.

In the case of extraction of the extruder screws, there is a hinged system that can be opened which allows, only by extracting some of them, to be able to access the tips quickly. Therefore, only four screws will need to be handled, there are neither hot parts nor a certain weight to support.

Another not insignificant aspect is the lateral heating of the die. In many cases, and especially on the new high-productivity machines, the supply chain is very large and involves the possibility of different temperatures being encountered between the various areas, which in turn generate irregular flows with consequent spaghetti of different diameters. There are also resistances positioned laterally that allow you to vary the heating and compensate for this phenomenon.

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987