TECHNOLOGICAL CENTRE

Maris Technological Centre

TECHNICAL TRIALS FOR INNOVATION. YOUR IDEAS BECOME REALITY IN OUR LABORATORY

Our Technological Centre carries out innovative and improving analysis of each production process which involves co-rotating twin-screw extruders. The Centre makes use of a highly qualified technical staff, who are in a position to solve both the internal and on-site problems, such as start-up, ordinary and extra-ordinary assistance, Customers visits supporting the Commercial Department.

Among the primary activities of the Technological Centre are those for the process optimisation in the study of new productive applications for our machines. The Centre collaborates with Public and Private Corporations, national and foreign, for the development of important research projects among which – in addition to those connected to the compounding of plastic materials - those for the use of co-rotating twin screw extruders for the production of vulcanising rubber, for the development of a rubber de-vulcanising process, for the continuous production of solvent base adhesive, and for polymerisation processes.

Thanks to the creativity, the know-how and the technicians working in the two parts of the Centre, the Technological Laboratory and the Materials Characterization Laboratory, we are ready to take up any additional challenge to go beyond new technological barriers.

THE TECHNOLOGICAL LABORATORY

The Technological Center has four extrusion lines at disposal:

- TM20 Hi-Tech - D/d 1,55: a purely laboratory extruder

- TM30 - D/d 1.55 high torque: laboratory or small industrial production extruder

- TM40/41 high torque, which can be configured with both a D/d 1.55 and a D/d 1.65: industrial production extruder

- TM58 - D/d 1.55 high torque: extruder for industrial production

Available equipments include:

- Wide choice of gravimetric feeders for both solids and liquids

- Single screw extruder

- Underwater cutting system

- Water-ring cutting system

- Air/water head cutting system

- Remote cutting system

- Vacuum and high vacuum pumps

- Gear pump

- Screen-changer

- Calender with conveyor belt

- Turbomixer and slow mixer

- Mill

To support the R&D activities, the Technological Center also uses an innovative process simulation software.

THE CHARACTERISATION LABORATORY

Besides the Technological Laboratory we put at disposal the Characterization Laboratory, for evaluating, in real time, the results of the trials as they are carried out on the extrusion lines.

The laboratory is able to make the characterisation:

- morphological (using a reflection microscope and a transmission microscope assisted by image analysis software)

- rheological analysis (the Center has a Melt Index, a capillary rheometer and a rotational viscometer)

- mechanics (using a dynamometer to measure elongation, bending and compression, two durometers - a Shore A and a Shore D - an Izod pendulum and a Vicat-HDT); there is also an injection molding machine on which a standard mold for ASTM specimens is mounted

- degree of crosslinking in a polymeric / rubber matrix (by solvent extraction).

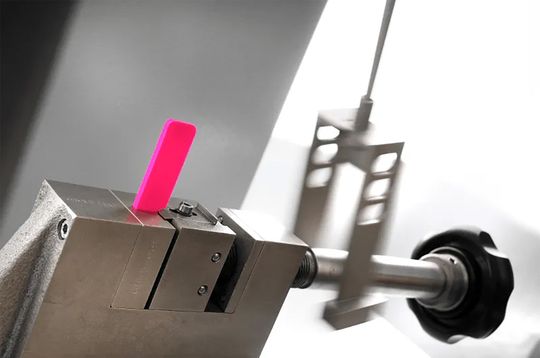

- dispersion of the fillers in the polymeric matrix, Maris Filter Test: measurement of the Pressure Index for clogging of a filter performed on a small quantity of undiluted Masterbatch / compound. We have in fact patented this type of fast analysis using the capillary rheometer, at the outlet of which there is a small metal filter. The lower the clogging speed of the filter, the better the product quality in terms of dispersion and distribution of fillers and / or pigments.

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987