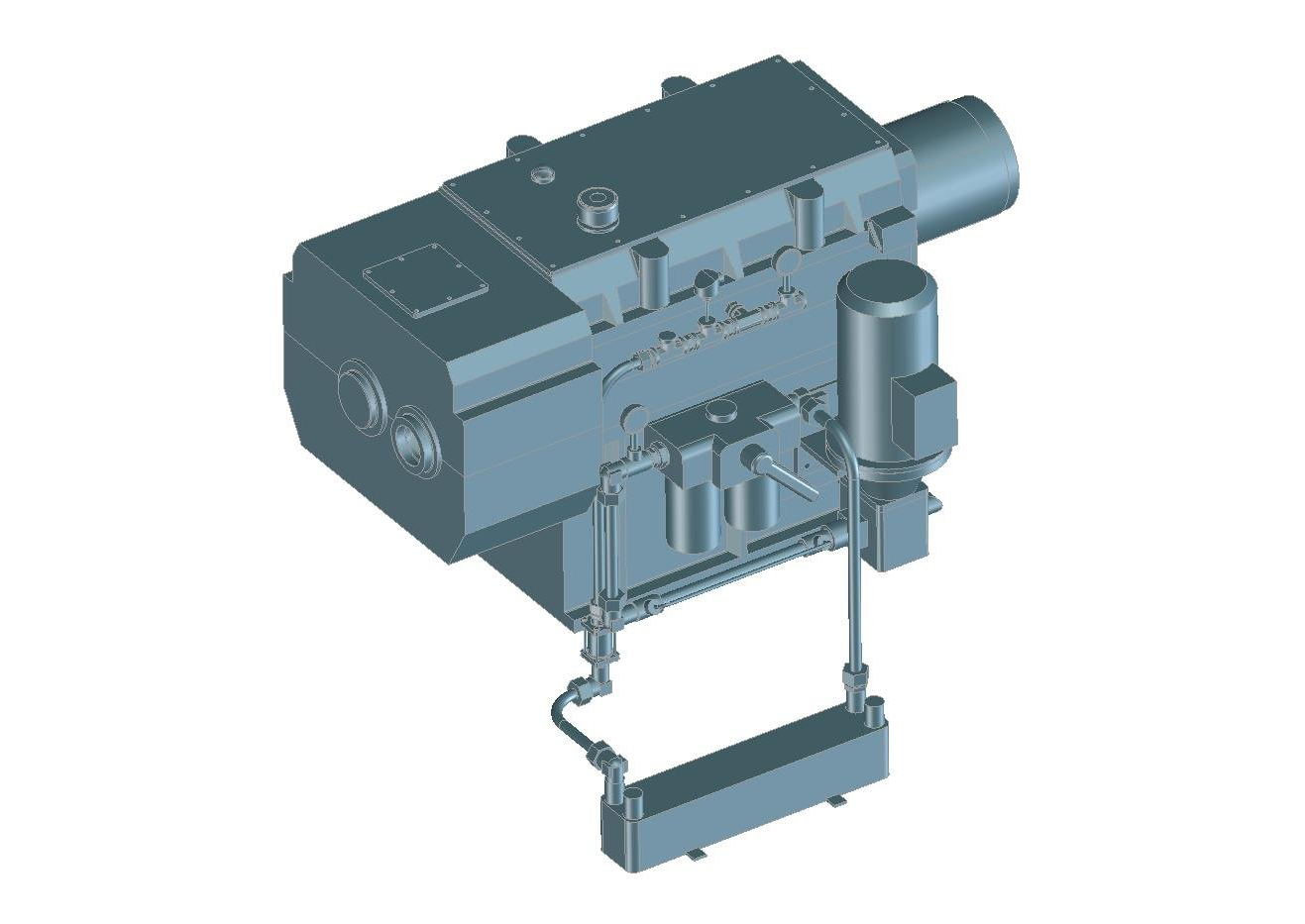

Gearbox

Our gearboxes are built and designed in-house in-house.

Co-rotating twin screw extruders require special gearboxes that can transmit the high torque density required by this type of machine.

The gearbox is designed using design and calculation programs that allow to obtain the expected results and withstand the stresses to which it will be subjected. The design is carried out by calculating the parts in real dimensions and on three-dimensional models.

These are special gearboxes where the motion is divided between various power branches and rejoined to be able to transmit the power to the two screw shafts. This generates a very complex gearbox with special devices and adjustments to ensure that each screw shaft receives exactly half the power.

The high torque density requires the use of advanced materials and treatments that must be controlled. By manufacturing the parts entirely, building them and machining them in-house, we can evaluate all aspects of the manufacturing process.

In the same way, all the gearboxes are dimensionally checked by our internal testing.

The lubrication system is placed outside the reducer and will bring the oil to the individual parts. The lubrication system has sensors to prevent any malfunctions from damaging the gearbox.

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987