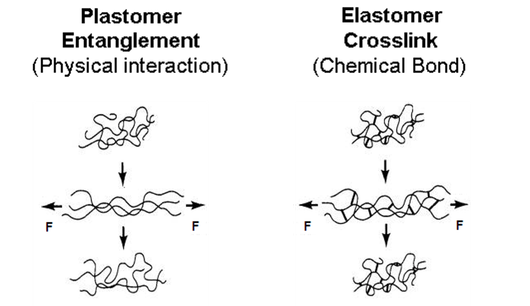

Maris thermo-mechanical process is a 100% green approach that does not involve the use of chemicals. This particular process is made possible thanks to the different chemical-physical characteristics of the CC, CS and SS bonds, specifically: a marked difference in terms of elastic bonding constant (kcc≈100> kcs> kss≈3) and an energy of different bond (370, 310 and 270 kJ / mol respectively).

Application range

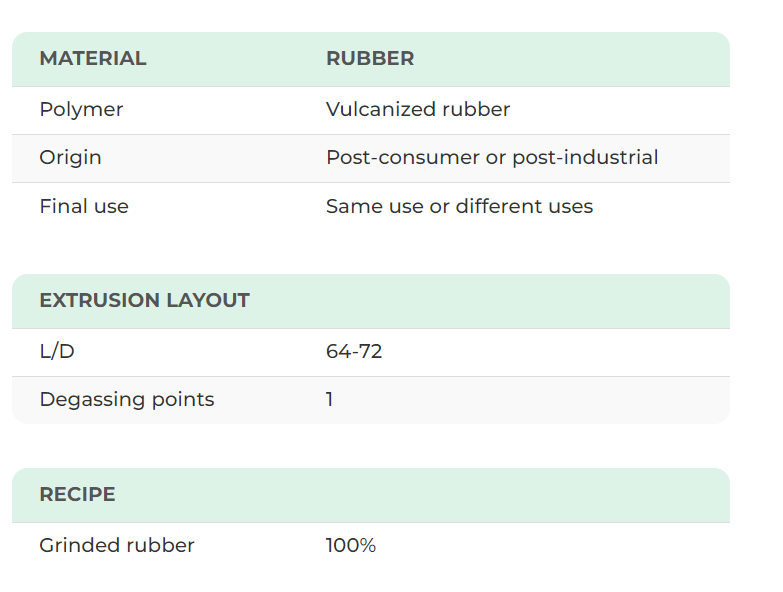

Thanks to Maris devulcanization process, the following materials can be recycled:

- ELTs – End of Life Tires

- Car tires

- Truck tires

- Off road tires

- ACM – Polyacrilic Rubber

- BR – Butadiene Rubber

- EPDM – Ethylene Propylene Diene Monomer

- FKM – Fluoroelastomers

- IIR – Butyl Rubber

- IR – Isoprenic Rubber

- NR – Natural Rubber

- Q – Silicone Rubber

- SBR – Styrene Butadiene Rubber

From chemical and rheological analysis carried out on devulcanized materials, it is found that the devulcanization yield can reach 60-80%.

The devulcanized material can be reused in the same original application, from 15 to 50% mixed with the virgin rubber while maintaining the desired mechanical properties. For different final applications it is possible to use devulcanized rubber in a blend with percentages higher than 50%.

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987