MASTERBATCH

For the production of Masterbatches it is fundamental to define the most suitable feeding layout. The decision ultimately depends on the level of investment, but also on the quality required.

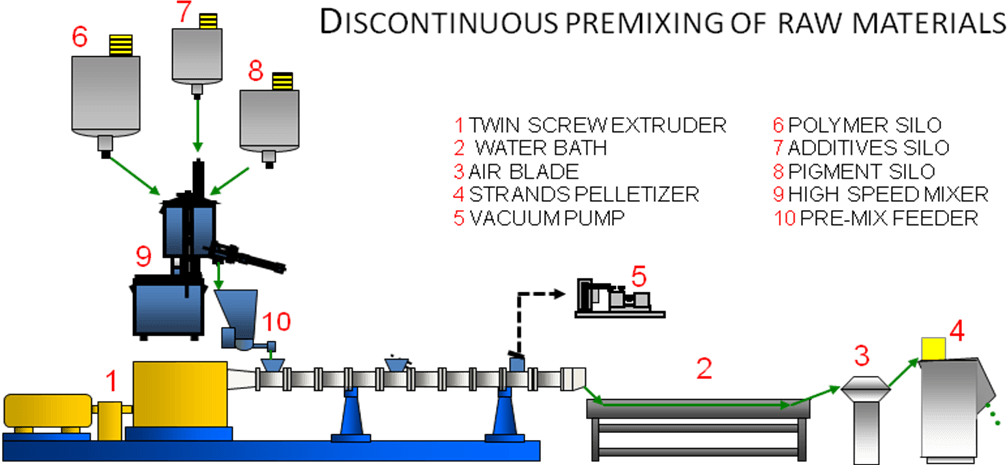

· Raw materials discontinuous pre-mixing: solution aimed at reducing the engineering costs or to produce, on the same equipment, a number of different formulations.

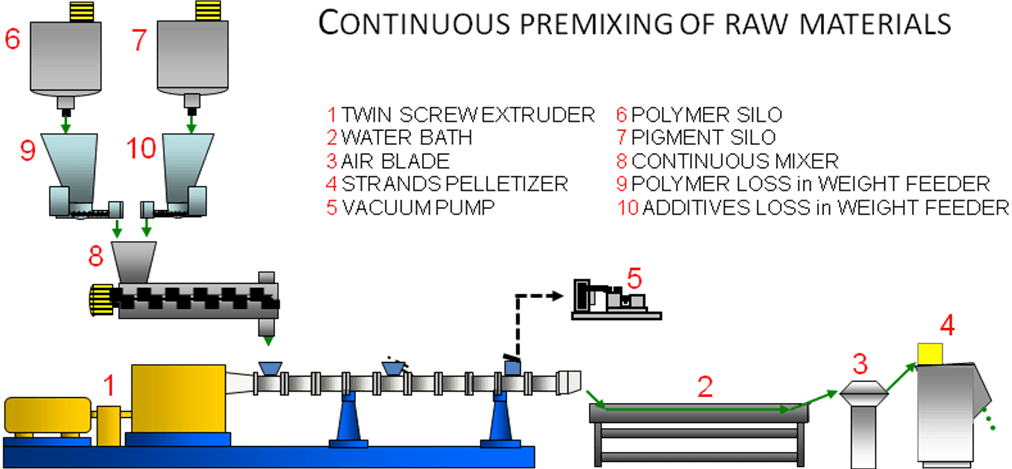

· Raw materials continuous pre-mixing: solution which exploits a single feeding point on the extruder. It is suggested to produce large quantities of material, with a limited number of formulations, while maintaining the quality of the batch mixing.

·

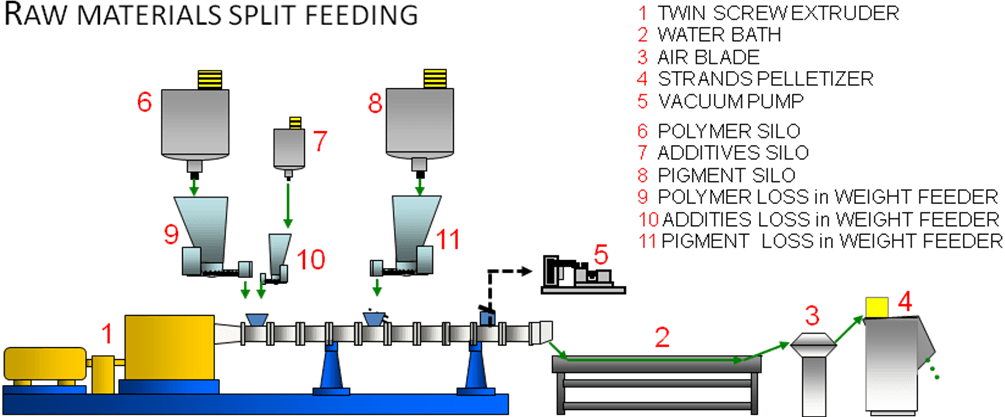

Raw materials split feeding: solution that is economically more expensive, but unquestionably more advantageous in terms of output and, in a number of cases, also in terms of quality. It is preferable when the equipment is operated exclusively for a single class of products.

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

OUR COROTATING TWIN SCREW EXTRUDERS CAN PRODUCE THE FOLLOWING MASTERBATCHES:

- MASTERBATCH ORGANIC PIGMENTS

- MASTERBATCH INORGANIC PIGMENTS

- WHITE MASTERBATCHES

- BLACK MASTERBATCHES

- MASTERBATCH CARBON BLACK

- TITANIUM OXIDE MASTERBATCH

- NON-POLYMERIC MASTERBATCHES

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987