Barrels and screws

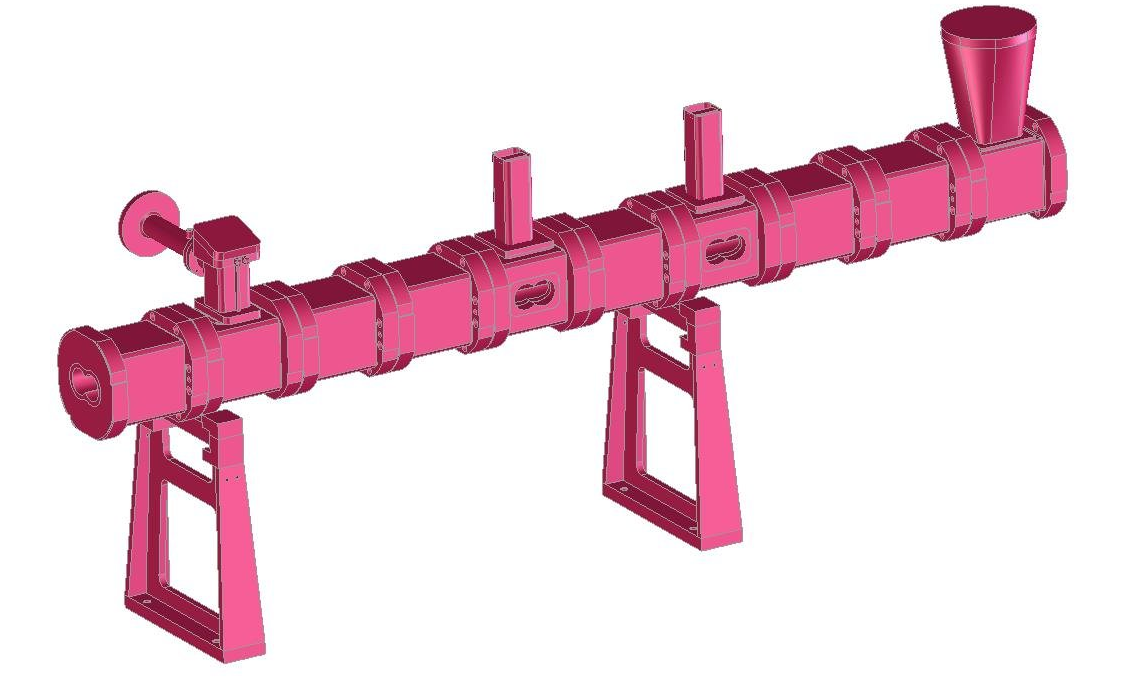

The barrel, which constitutes the process area, is configured through the use of different modules having different functionalities.

From the construction point of view, they are available in two geometric shapes: round or square.

The different shapes also distinguish the use of different types of electrical heating elements. In the case of the round shape, ceramic or cast (aluminium, steel or bronze) heating elements can be used, while candle or cast (aluminium, steel or bronze) heating elements can be used for the square barrel.

Regarding the construction materials - depending on the applications – there are more options: from the nitrided barrel to barrels with removable inserts in special anti-wear, anti-corrosion steels or the combination of the two properties. These steels range from fully hardened materials to HIP and bimetallic materials: we are always at the forefront in the search for new materials to improve the performance of our extruders.

The screws are positioned inside the barrels, consisting of two shafts and modular screw elements. These elements are made with the same steels used for the barrels and can have multiple geometries and functions: transport, kneading and special elements.

F.lli Maris S.p.A.

Corso Moncenisio, 22

10090 Rosta (TURIN) - Italy

TEL: +39 011 956 7925

FAX: +39 011 956 7987