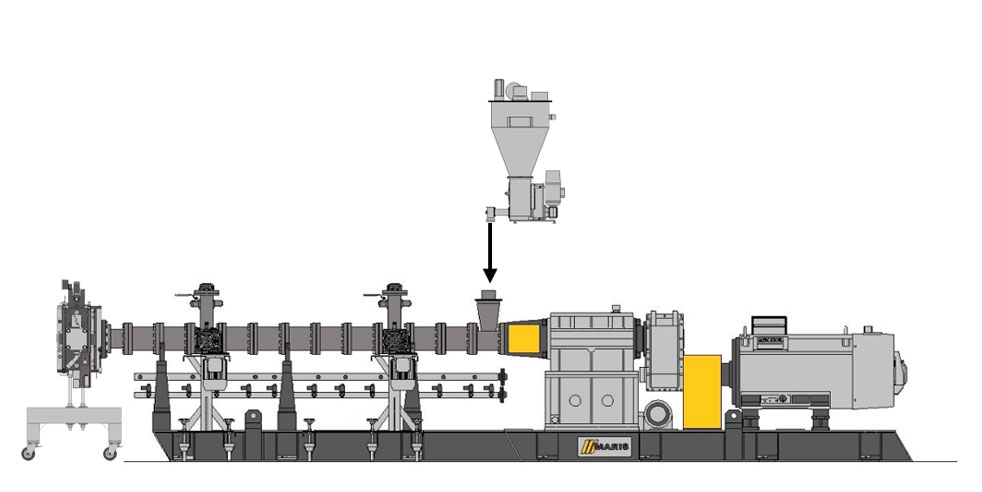

Thanks to Maris co-rotating extruder, PET bottles can be recycled to produce 100% green new ones. In the PET recovery, reducing traces of water with high vacuum pumps minimizes the loss of intrinsic viscosity, by guaranteeing high performance for the material.

To safeguard the mechanical properties of the material, our extruders dedicated to the recycling of PET bottles are equipped with advanced high vacuum pumps, ensuring degassing of the material in multiple points. This prevents degradation of the PET polymer chains caused by moisture. Furthermore, the addition of mineral fillers or additives allows the enhancement of the material properties, by making it suitable for different applications.

| MATERIAL | BOTTLES |

|---|---|

| Polymer | PET |

| Origin | Post-consumer or post-industrial |

| End use | Bottles or different uses |

Extruder Setup | |

|---|---|

| L/D | 36- 40 |

| Degassing Points (High Vacuum Pumps) | 2 |

| Cutting System | Spaghetti/Sunderwater |

| Filter Changer | Automatic |

| RECEPT | |

|---|---|

| Milled bottles | 100% |