Development of an advanced extrusion process for the reduction of volatile and semi-volatile organic compounds of recycled HDPE from fuel tanks

Plastic fuel tanks of vehicles are typically made by high density polyethylene (HDPE). The easiness of the dismantling procedure from end-of-life vehicles and the intrinsic recyclability of HDPE allows them to be accounted in principle in the “white list” of recyclable components.

Environmental assessment of rubber recycling through an innovative thermo-mechanical devulcanization process using a co-rotating twin-screw extruder

Under the umbrella of the transition toward a circular economy, the evaluation of the environmental sustainability of processes aiming to the recycling of materials is essential. Rubbers, like ethylene-propylene diene monomer (EPDM), represent a class of materials that have become an environmental, social and economic issue, so the evaluation of the end-of-life management of these materials is of primary relevance.

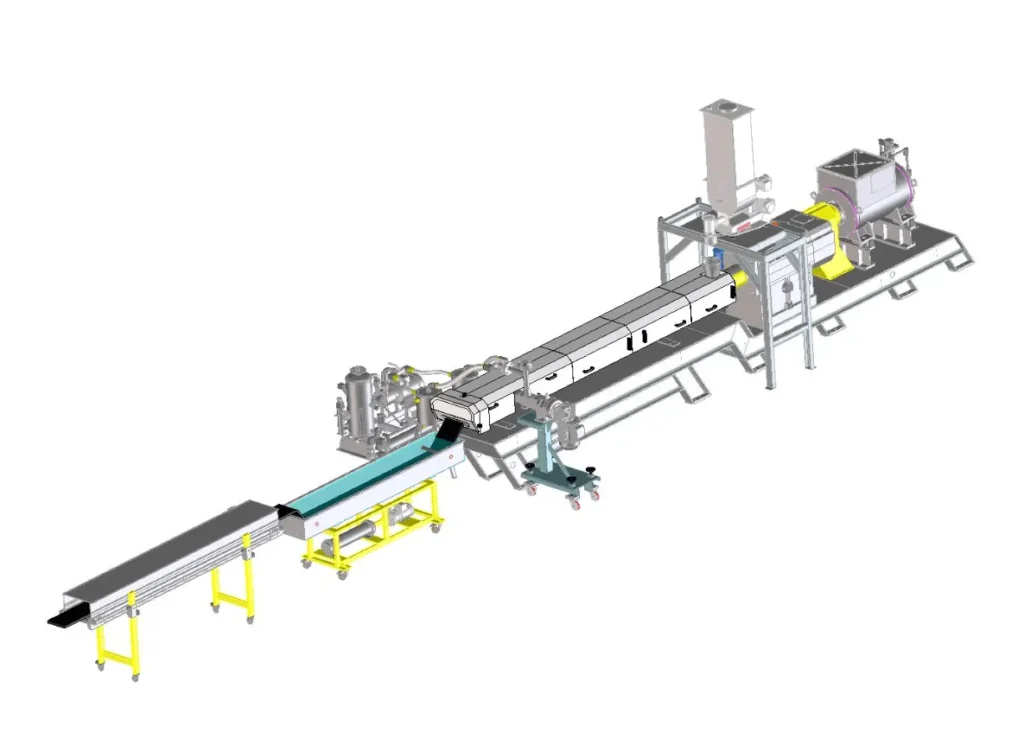

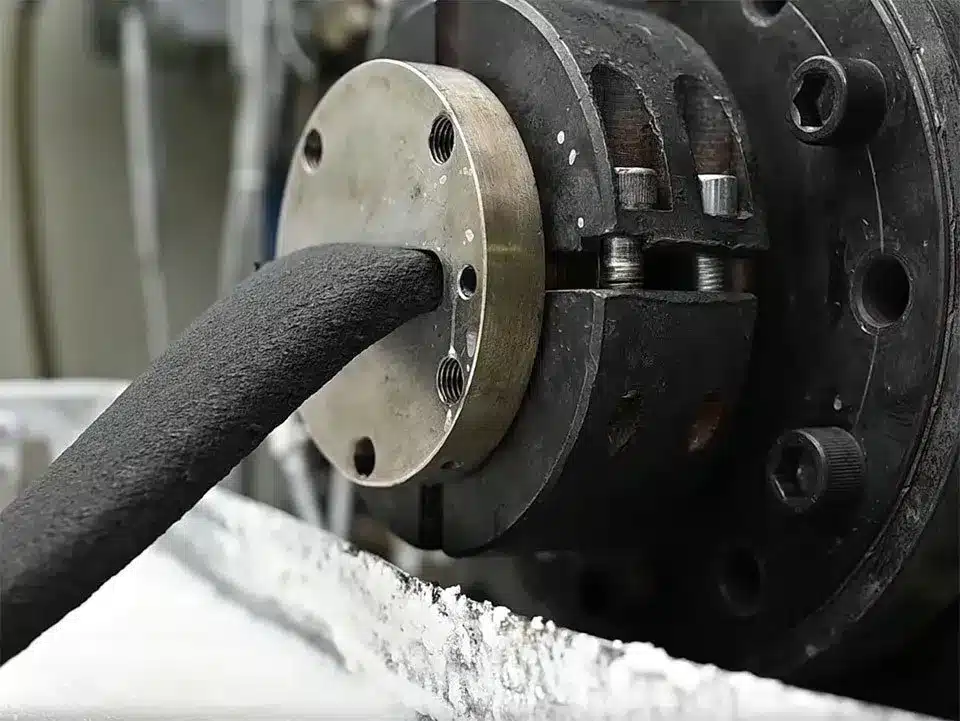

Recycling of EPDM via Continuous Thermo-Mechanical Devulcanization with Co-Rotating Twin-Screw Extruder

Devulcanization represents the recycling of choice for a homogenous rubber waste stream because it allows revulcanization of samples previously devulcanized, making the life of the rubber virtually endless, according to the principles of circular economy.