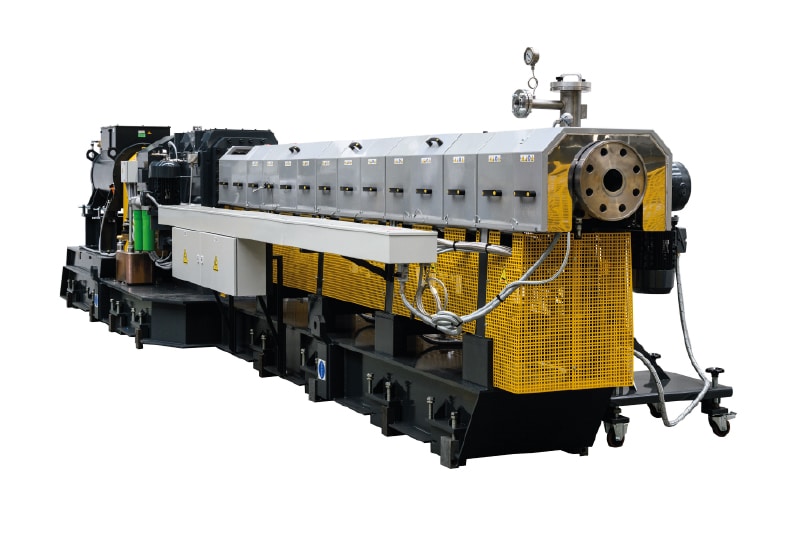

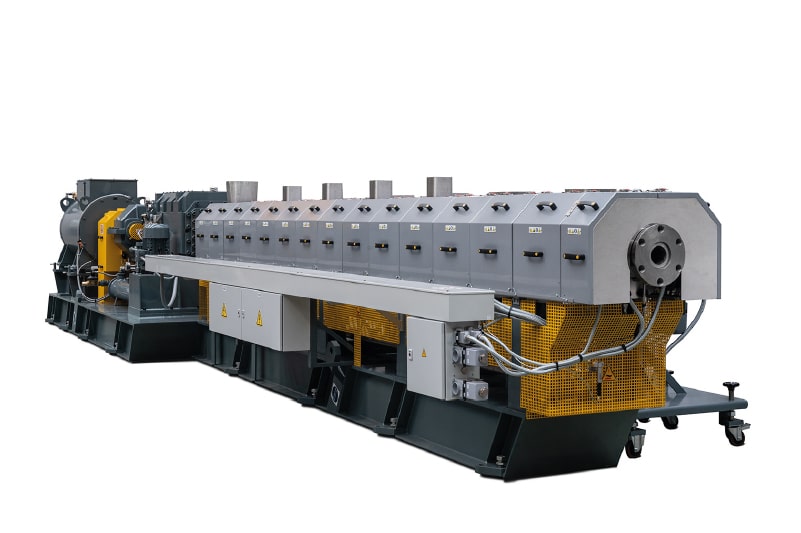

Maris extrusion lines are custom designed. Each system is created by listening to the customer’s needs, with the aim of offering reliable, flexible and high-performance solutions, ideal for compounding, pelletising and recycling plastic and rubber.

We create systems with attention to every detail, from design to commissioning, providing comprehensive technical support and after-sales service. With over 60 years of experience, we are the ideal partner for those seeking innovation, energy efficiency and the highest quality.

Each line is the result of a structured and proven process, which allows us to build solutions that are perfectly aligned with your production objectives.

It all starts with listening. We analyse your production process, the materials involved and your performance objectives. Through direct discussion, we gather all the technical information needed to define clear and achievable goals. This phase is essential for designing a line that is consistent with your actual operational needs.

Based on the data collected, we develop a tailor-made project, calibrated to the type of polymer, the required productivity and the application context. Every detail is designed to maximise efficiency, compound quality and operational flexibility. No line is standard: every Maris solution is unique, just like your process.

We manufacture all mechanical components in-house. Before delivery, each line is fully assembled and tested at our factory to check its actual performance and ensure quick, safe start-up without any surprises.

From installation in the field to after-sales service, we remain at your side every step of the way. Our technical team takes care of commissioning the system, trains your staff and provides ongoing support throughout the entire life cycle of the system. For us, a completed project is just the beginning of a lasting partnership.

Our co-rotating twin-screw extruders are designed to tackle the most complex challenges in plastic and rubber compounding, including recycled materials and high-viscosity polymers.

The screws and barrels feature high modularity, with interchangeable segments made of special wear-resistant, corrosion-resistant, or bimetallic steels. The screw profile, which represents the heart of the extruder, is optimized through conveying and mixing screw elements that define precise functional zones: feeding, melting, dispersion, distribution, and degassing..

Thanks to a modular structure and high operational flexibility, they are perfectly suited for complex processes with continuous feeding.

Maris extrusion lines are designed to offer high performance, versatility and absolute precision in every type of application, with a strong focus on process customisation.

Each system is tailor-made to guarantee:

The modularity of the components, combined with the flexibility in the configuration of screws, cylinders and feed modules, allows us to build unique lines, designed to meet the real needs of the customer, for both virgin and recycled materials.

With over 60 years of experience, Maris is able to support you from the technical definition phase to process optimisation, providing turnkey solutions with know-how that makes the difference.

Our lines can process a wide range of thermoplastic materials (virgin, recycled, or compounded), including:

The ability to handle complex, sensitive, or reactive materials makes our lines ideal for the most demanding sectors: automotive, electronics, construction, medical, packaging, and environmental sustainability.

Choosing Maris means finding a partner with over 60 years of experience in the extrusion and compounding sector. We design tailor-made systems, offering maximum flexibility and truly customised solutions that go beyond standard offerings. Our commitment to innovation translates into proprietary technologies and a constant focus on materials and process research. We offer comprehensive technical support, both before and after installation, guaranteeing global assistance anywhere in the world. Furthermore, we develop systems designed for the circular economy, promoting sustainable production processes geared towards efficient recycling.

We are at your disposal for any requests, information or support.

Please do not hesitate to contact us using the form below or the contact details provided.

Your satisfaction is our priority.

Personal data entered are processed by the owner of the website Maris Fratelli Spa – Corso Moncenisio 22 – 10090 Rosta (TO) – +390119567925 acting as Controller, for purposes associated with the provision of the services requested by You (without limitation: asking information, registering to the website to receive advantages and offers, obtaining quotations, making payment, purchase goods and receiving them at the address specified by You, making a reservation, exchanging documents).

Furthermore, the data provided by You, could be processed, on Your explicit consent only, for the purpose of sending business communications, by email o by text, concerning services provided by the Controller.

Processing operations will take place with electronic mode and will be made available to third parties (External Processors) inside and outside the EU, duly contracted and offering adequate security safeguards, necessary for the provision of essential services to satisfy Your needs. Said External Processors – whose list is available upon request – may belong to categories of people supporting the Controller in the delivery of the services offered through this website (such as, without limitation: software developers and website managers, carriers).

Furthermore, they will be processed for statistical analysis and direct marketing purposes – on an anonymous basis – as better specified in the cookie policy.

Accordingly, they are legitimate processing operations necessary to ensure a service meeting Your expectations. Data will be stored for the entire term of the services requested by You or for longer periods only where provided for by the Law. At any time, You may exercise the rights provided for by articles 15 – 22 of GDPR by writing to the Controller of the present web site.

In order to rectify or erase your personal data stored in the system used to supply the present web site, click here. The personal data You will insert in the form (including you email address) should be communicated to a company that acts as Processor on behalf of the Controller and that manage the website and the users’ requests.

Should You ask for Your data to be erased, we inform You that it may no longer be possible to continue providing You with the service requested.

Finally, we inform You that You can lodge a complaint with the Data Protection Authority if You believe Your rights have been violated.

***********************************

COOKIE POLICY

This Site uses technical cookies (i.e., necessary cookies) and with your consent also analytical and profiling cookies, which we and third parties will use – respectively – to enable certain key features of the Site, to obtain measurements of the Site performance or to provide you with promotions in line with your interests.

To accept, reject or select cookies according to purpose, use the controls in the cookie management pop-up banner.

In particular, to find out which cookies are installed within the preset site and express your preferences in this regard, select the ‘Settings’ command where you can also view the individual cookies issued in each category. To select the purposes you are interested in, use the box in the banner, and click on “Customise” to confirm your preferences.

Your preferences will be recorded in a Cookie Consent Management Platform (the “CMP”), which has been developed in accordance with the principles of the applicable data protection legislation and according to the privacy guidelines in order to allow you to exercise your choices in a granular manner. CMP allows you to give or to reject your consent to various types of cookies, which are identified and categorised according to the purposes for which the cookies are issued and used, making it easier and more straightforward to recognise them.

You may at any time withdraw or modify the consent given by clicking on the relevant CPM access icon that will appear on the Site. This icon will be displayed in the bottom left-hand corner, once you have expressed your preferences via the pop-up banner displayed when you access the Site.

The cookies used on this Site fall into the categories described below.

What are cookies

Cookies are small text files that are automatically placed on the user’s PC within the browser. They contain basic information about your Internet browsing and are recognised by your browser each time you visit the Site.Below you will find details of the cookies installed by this website and how to manage your preferences.

What cookies are for

Cookies are useful since they allow us to store your browsing preferences and thus customise the Site according to your needs by improving your browsing experience. For example, cookies can make the use of the Site more immediate and/or enable certain functionalities. For example, cookies may make it possible to avoid re-entering the same information several times during a visit. In certain cases, cookies may also make the advertisements displayed online more appropriate to the user or relevant to the user’s interests.Some cookies are necessary for the correct delivery of the Site or useful for a personalised use of the Site. In this case, their inhibition could compromise certain functionalities of the Site. Moreover, thanks to cookies, advertisements in line with your interests – cleared of your online activities and browsing habits – can be published on the Site itself, directly or through third parties.

Which categories of cookies are used on the Site

1 – Technical or necessary cookies:

the technical cookies described below do not require consent and are therefore installed automatically following access to the site.

– Cookies necessary for operation: cookies that allow the site to function properly, including allowing the user to have a functional browsing experience. For example, they keep the user logged in while browsing by preventing the site from requiring the user to log in several times to access subsequent pages.

– Statistical and Audience Measurement cookies: cookies that help understand, through data collected in an anonymous and aggregate form, how users interact with the Website by providing information about the sections visited, the time spent on the site, any malfunctions.

For instance, in some cases, Google Analytics cookies used by this site have been anonymised and are therefore equivalent to technical cookies.

2 – Functional Cookies

This category includes cookies that allow us to remember preferences you have selected while browsing, for example, they allow you to set your language. These cookies are only issued at the request of the user and with their prior consent. The user is free to give his or her consent to the installation of functional cookies and to withdraw it at any time, through CMP, without the possibility of visiting the Site and enjoying its contents being affected. However, if the user does not consent to these cookies, the use of certain functionalities may be affected.You can access the CMP at any time through the icon on the Site, where you will find a summary of the consents released that you can modify by clicking on the ‘Modify Consent’ button; at this point a screen will open allowing you to modify your preferences by choosing the categories of interest and with the ‘Settings’ button you can find out which functional cookies are released on the Site, their purpose and duration. Once you have made your choice, click on the ‘Customise’ button to confirm it.

3 – Analytical Cookies

Cookies in this category are used to collect statistical information, in non-aggregated form, on the use of the Site by users accessing the Site and on the way in which they navigate on the Site. As required by applicable Law, the prior consent of the user is required for the installation of third-party analytical cookies. If you give your consent to the installation of analytical cookies, the Controller will keep track of this consent by means of a specific technical cookie. In this way, it will be possible to avoid the repetition of the cookie banner during future visits to the Site. You can access the CMP at any time through the icon on the Site, where you will find a summary of the consents released which you can modify by clicking on the ‘Modify Consent’ button. At this point, a screen will open that allows you to modify your preferences by choosing the categories that interest you, and through the ‘Settings’ button you can find out which analytical cookies are released on the Site and thus obtain all the necessary information. Once you have made your choice, click on the ‘Customise’ button to confirm it.

4 –Profiling Cookies

Profiling cookies are used to group users into homogeneous categories based, for example, on user preferences. Such cookies can be used – among other things – to send advertising messages in accordance with the user’s online behavior and browsing interests. In accordance with applicable Law, the prior consent of users is required for the installation of profiling cookies. The user is free to give his or her consent to the installation of profiling cookies and to withdraw it at any time – through CMP – without the possibility of visiting the Site and enjoying its contents being affected. In the event that the user gives his consent to the installation of profiling cookies, the Data Controller will keep track of this consent by means of a specific technical cookie. In this way, it will be possible to avoid the repetition of the cookie banner during future visits to the Site.Profiling cookies are installed by the Data Controller and by third parties acting as independent data controllers (third-party cookies).You can access the CMP at any time through the icon on the Site, where you will find a summary of the consents issued that you can modify by clicking on the ‘Modify Consent’ button. At this point a screen will open that allows you to modify your preferences by choosing the categories you are interested in and via the ‘Settings’ button to obtain more information on the third parties that install profiling cookies, on the individual cookies issued and on their duration. Once you have made your choice, click on the ‘Customise’ button to confirm it.

In addition, by going http://www.youronlinechoices.com/it/le-tue-scelte you can find out about behavioral advertising as well as deactivate or activate the cookies of the listed companies that work with website operators to collect and use information for advertising.

Remember that you can also manage your cookie preferences via your browser.

Below, you will find more detailed instructions on how to manage cookies for the most popular browsers.Browser manufacturers may update or change the references in the links below from time to time, so please always check the instructions provided by the manufacturers of the browsers you use to understand how to set cookies.

If you use the Edge browser:

• You can find out how to manage cookies, delete them, block them, select them by using the settings of this browser at the following link: https://support.microsoft.com/it-it/microsoft-edge/eliminare-i-cookie-in-microsoft-edge-63947406-40ac-c3b8-57b9-2a946a29ae09.

If you use the Firefox browser

• To find out how to manage cookies via this browser settings: https://support.mozilla.org/it/kb/Gestione%20dei%20cookie.

• To learn how to manage the privacy settings panel and inhibit the tracking of your online activities https://support.mozilla.org/it/kb/Impostazioni%20di%20Firefox%20-%20pannello%20Privacy.

• To find out how to activate and deactivate cookies: https://support.mozilla.org/it/kb/Attivare%20e%20disattivare%20i%20cookie.

• To find out how to delete cookies: https://support.mozilla.org/it/kb/Eliminare%20i%20cookie.

• To find out how to block cookies: https://support.mozilla.org/it/kb/Bloccare%20i%20cookie.

• To find out how to deactivate only third-party cookies: https://support.mozilla.org/it/kb/Disattivare%20i%20cookie%20di%20terze%20parti.

If you use the Safari browser

• To find out how to manage cookies via this browser settings: https://support.apple.com/it-it/guide/deployment/depf7d5714d4/web.

If you use the Google Chrome browser

• To find out how to manage cookies via this browser settings: https://policies.google.com/technologies/cookies?hl=it&gl=it#managing-cookies.

• To find out how to activate private browsing mode: https://support.google.com/chrome/answer/95464?hl=it.

• To find out how to delete cookies, block them selectively if necessary, receive notifications about your cookie settings: https://support.google.com/chrome/answer/95647?hl=it.

Last updated: 08/06/2023.