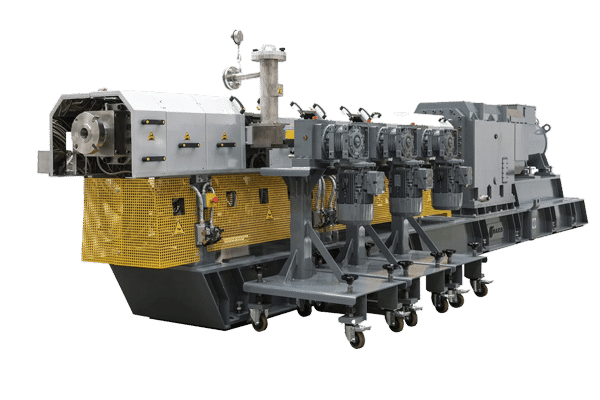

We are international leaders in the manufacturing of complete extrusion lines, especially when it comes to co-rotating twin-screw extrusion lines, for the compounding and granulation of recyclable and non-recyclable materials.

Our constant commitment to research and the extensive experience gained have strengthened our leading role in the compounding sector.

When it comes to high quality mixing, plastics and rubber, Maris extruders are a standard.

For over sixty years, we have been passionately dedicating to providing professional services and tailor-made solutions. Our cutting-edge extrusion lines and constant research make us a reference in the mixing of high-quality materials. Our ongoing commitment translates into the specialization and production of corotating twin-screw extrusion plants, by turning compounding into our mission.

We adapt each service to your production needs, combining technological skills and experience to provide tailor-made solutions.

Thanks to a constantly available customer service, we build relationships based on trust and security over time.

Our long history in the field represents the solid foundation where all our skills are put at your complete service.

We offer you our complete support, from the supply of spare parts to extraordinary maintenance, always putting our experience at your disposal.

We commit to the most innovative technological challenges by using our over 60 years of know how to provide cutting-edge solutions.

We produce all the fundamental parts of our products internally, with high-level production and quality processes, by granting a total control over the 100% of our technology.

The experience at the core of Maris path within the extrusion world results into our commitment to ensure the highest quality and product innovation.

The quality of the products lies in the production sectors in which we can boast the use of our extruders.

Our production lines are characterized by a consolidated technology with a high degree of reliability and a high-performance laboratory line.

We provide our customers with a technological center to carry out tests on all types of materials and develop new production processes.

At a time when the recovery of plastic materials plays a key role in the Circular Economy – thanks to our ideas, our products and our service –

we contribute to never interrupting the innovative flow of the creation of new and recycled materials.

This is why we have been studying and designing specific extrusion lines for plastic materials to achieve this goal.

Recycling is the most efficient solution for reusing polymeric materials. EVOREC (EVOLUTED RECYCLING) is the result of the need to transform waste into compounds as required by the market. Our specialized plastic and rubber lines are proof of Maris commitment to the Circular Economy and to advanced recycling.

A company asset lies in the concept of ‘Team’ which – alongside with technology – is what allows us to deal with every request.

We have turned the customer service into our business philosophy, by identifying needs and providing solutions that grant complete satisfaction in terms of results.

We have always been committed to the most innovative technological challenges thanks to the experience and know-how gained over the years. All resources are involved to seek the best performing solutions: the result is a set of increasingly optimized production processes that allow our customers to effectively respond to the needs of an increasingly demanding and sophisticated market.

For any request, information or support, we are at your disposal.

Please do not hesitate to get in touch with us through the form below or using the contact details provided.

Your satisfaction is our priority.