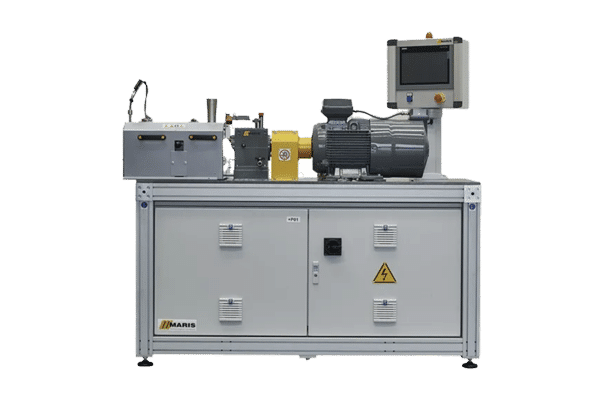

Our laboratory extruder, in line with current industrial trends that transfer the experiences gained in the laboratory to production, represents the essence of decades of experience in the sector of co-rotating twin-screw extruders. The characteristics of flexibility and reliability of this machine make it an instrument conceived and created for research, while retaining all the qualitative, constructive, functional and operational characteristics of our production plants, so as to faithfully reproduce on a small scale the behaviors and performance.

Specific torque (Nm/cm3)

10

Max. rotational speed (rpm)

1500

D/d

1,55

Screw diamater (mm)

20

Typical fields of application *

Laboratory

* the fields of application associated with the Series are to be considered indicative, as they depend on the formulation, viscosity of the materials and the specific process limits.

One of the most interesting aspects of the TM20 Hi-Tech is its wide flexibility, which allows rapid configuration changes, according to the raw materials used and the type of process. All this is possible thanks to mechanical, modular and interchangeable components that do not require the intervention of personnel with a specific mechanical training.

Designed and built to be used in laboratories, it is highly silent and is therefore also suitable for non-industrial environments such as training and research facilities.

The TM20 Hi-Tech co-rotating twin-screw extruder enables the check and the analysis of all processes to be carried out on industrial-scale production lines.

The gearbox has an oil bath lubrication system, while the barrel is cooled through a water circulation circuit, which – starting from a main distributor – cools each part of the barrel individually and is heated electrically by means of heaters.

The industrial scale-up of this laboratory machine can be determined by performing specific calculations. These calculations – influenced by the type of material to be extruded – depend on the process volume and energy factors.

Fill out the form to request a personalized quote. Our trained and available staff will promptly answer all your questions, offering you the support you need.