More than 60 percent of plastic waste comes from packaging. Polyolefin recycling spans a variety of sources, including rigid and flexible packaging, textiles, technical artifacts and more, providing ample opportunities for reuse. With Maris’ twin-screw corotating extruders, polyolefin-based packaging can be recycled to produce plastic films again.

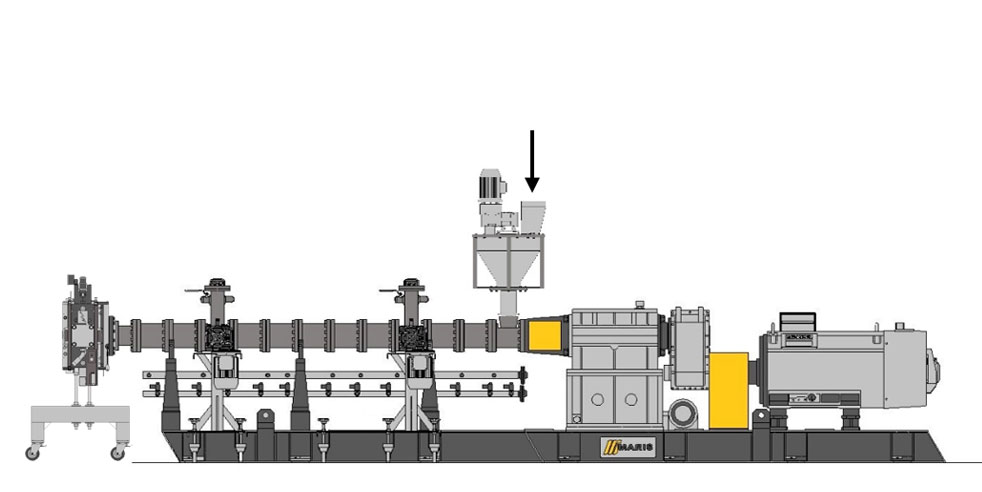

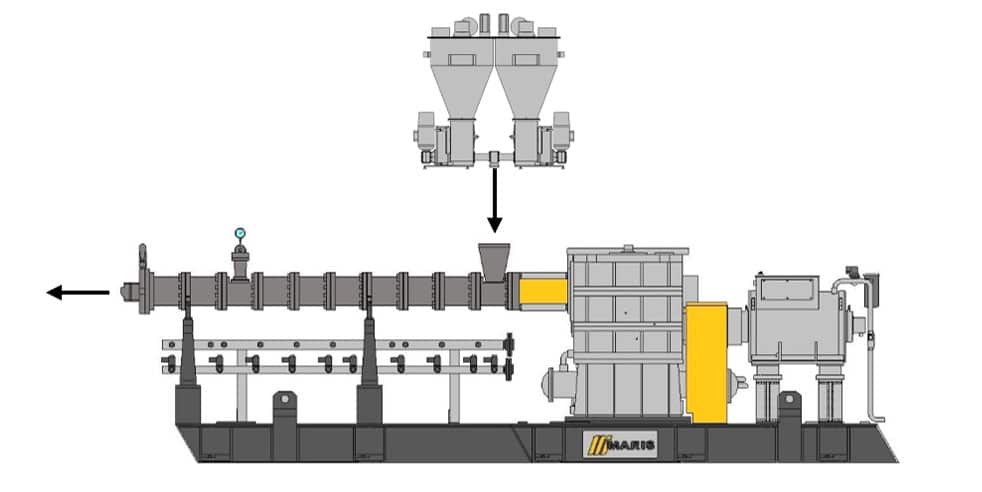

Maris extruders not only enable the recycling of polyolefin-based packaging for the production of new films, but offer the possibility of incorporating mineral fillers and additives to improve material properties through the addition of one or more side feeders. In the case of post-consumer material, the extruder is equipped with filtration to ensure the elimination of contamination.

| MATERIAL | IMBALLING |

|---|---|

| Polymer | LDPE or PP |

| Origin | Post-consumer or post-industrial |

| End use | Packaging or different uses |

EXTRUSER INSTALLATION | |

|---|---|

| L/D | 36 - 48 |

| Special Feeding | Forced Feeding (if the material is not densified) |

| Degassing Points | 1 or 2 |

| Cutting System | Spaghetti/Sunderwater |

| Filter Changer | Automatic |

| FORMULATION | |

|---|---|

| Milled polyolefins | From 30 to 100 % |

| Fillers or additives | From 0 to 70 % |

The common presence of PP contamination can complicate the market entry of recycled HDPE. With Maris corotating twin-screw extruders, we overcome this challenge by processing and adding, in different percentages depending on the level of contamination, a polymeric compatibilizer that significantly improves the mechanical performance of the material.

| Material | BOTTLES DETERGENT |

|---|---|

| Polymer | HDPE contaminated with PP |

| Origin | Post-consumer |

EXTRUSER FURNITURE | |

|---|---|

| L/D | 36 - 40 |

| Degassing Points | 1 |

| Cutting System | Spaghetti/Sunderwater |

| Filter Changer | Automatic |

| FORMULATION | |

|---|---|

| Milled Polyolefins | 92 to 98 % |

| Compatibilizing | 2 to 8 % |