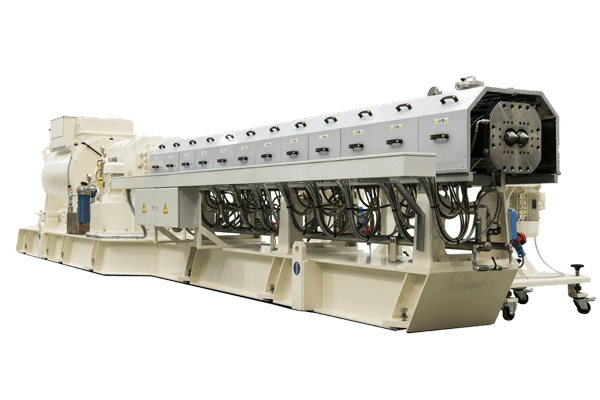

Our extruders are the ideal choice for the compounding of plastic and rubber. Dynamic and flexible, they adapt to different processes with continuous feeding. We offer customized and versatile solutions, supported by technological know-how and experience, granting long-term reliability and safety with our range of extruders for plastic and rubber, also suitable for recycling.

La nostra esperienza pluridecennale ci consente di fornire soluzioni su misura per i nostri estrusori, supportate da un know-how tecnologico avanzato. Gli estrusori bivite co-rotanti Maris sono progettati per offrire versatilità, affidabilità e prestazioni elevate nella lavorazione di materie plastiche, compound e gomma.

Ogni estrusore è il risultato di un approccio progettuale orientato alle sfide emergenti, al fine di garantire affidabilità e successo a lungo termine nel campo dell’estrusione delle plastiche e gomme.

Maris è leader internazionale nella realizzazione di impianti di estrusione completi. Ci siamo specializzati nella produzione di estrusori bivite co-rotanti per il compounding e il riciclo. La nostra dedizione alla ricerca continua e l’ampia esperienza acquisita ci hanno permesso di consolidare il nostro ruolo guida nel settore del compounding.

I nostri estrusori sono in grado di lavorare una vasta gamma di materiali plastici, inclusi quelli riciclati, mantenendo elevati standard qualitativi. La flessibilità delle nostre macchine le rende ideali per diverse applicazioni industriali, garantendo efficienza e sostenibilità nei processi produttivi.

Coppia specifica (Nm/cm3)

15

Velocità di rotazione max (rpm)

1300

Settori di tipica applicazione

Compounding

Riciclo plastica

Devulcanizzazione gomma

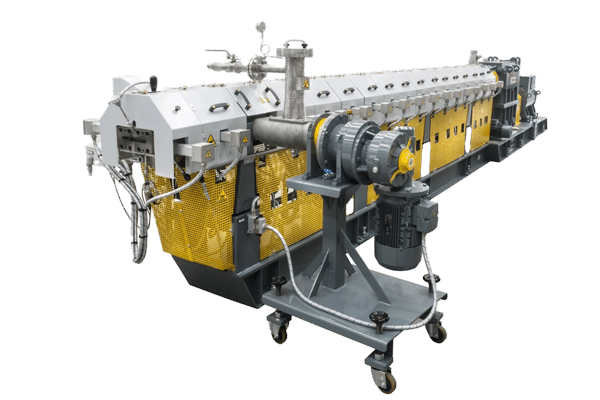

Specific torque (Nm/cm3)

13

Max. rotational speed (rpm)

1300

D/d

1,55 and 1,65

Typical fields of application

Compounding

Biomaterials

Bi-oriented films

Plastic recycling

Rubber devulcanization

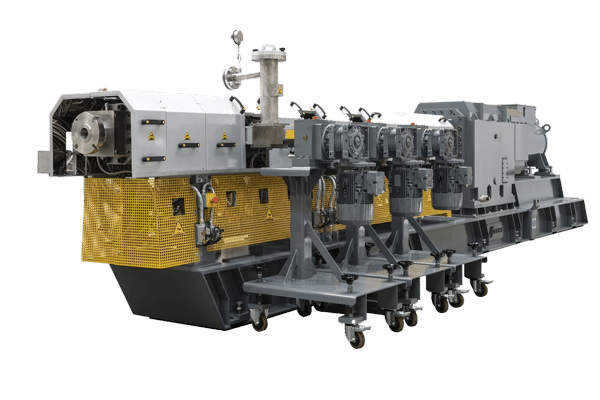

Specific torque (Nm/cm3)

Max. rotational speed (rpm)

11

Typical fields of application

1300

D/d

1,55 and 1,65

Typical fields of application

Compounding

Masterbatch

Biomaterials

Bi-oriented films

Microporous film

Solvent-based adhesives

Hot-melt adhesives

Duct tape

Plastic recycling

Rubber devulcanization

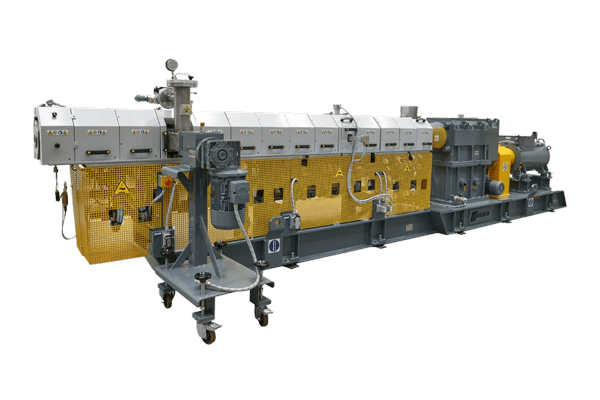

Specific torque (Nm/cm3)

8

Max. rotational speed (rpm)

1200

D/d

1,55 – 1,65 – 1,78

Typical fields of application

Compounding

Masterbatch

Biomaterials

Bi-oriented films

Microporous film

Solvent-based adhesives

Hot-melt adhesives

Plastic recycling

Reactive extrusion

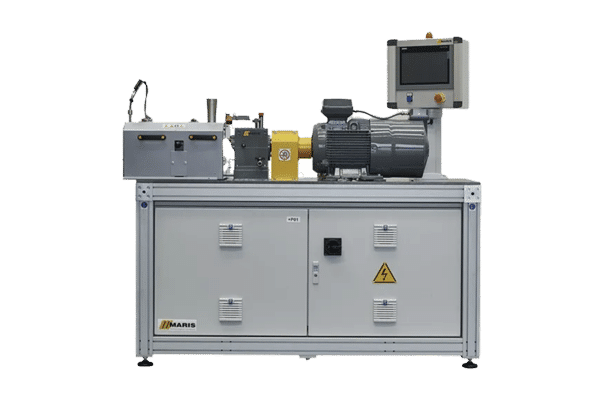

TM-20HiTech is the result of 60 years of experience in the field of co-rotating twin-screw extruders: cutting-edged and in tune with current industrial trends, it stands out for its synthesis between experience and innovation. Designed for research, it maintains the quality, manufacture and performance of our production facilities, offering a faithful small-scale replica.

Specific torque (Nm/cm3)

10

Max. rotational speed (rpm)

1500

D/d

1,55

Screw diameter (mm)

20

Typical fields of application

Laboratory

Maris co-rotating twin-screw extruders grant durable and high-quality performances. Our technical expertise, supported by the technological laboratory, allows us to flexibly adapt to the specific needs of customers. With a continuous spare parts service and pre- and post-sales support, we offer a lasting investment. The versatility of our machines, also appreciated in recycling, reflects our know-how and projective approach to emerging challenges. Choosing Maris means investing in innovation, reliability and long-term success in the field of plastic extruders.

Fill out the form to request tailor-made consultancy and receive the technical details you need. Our team is ready to provide you with all the necessary information.